Transform Waste Into Value With Advanced Transformer Oil Recycling

The improvement of waste into value offers a pivotal opportunity within the electric market, especially via the lens of innovative transformer oil recycling. By using modern modern technologies, such as vacuum cleaner purification and filtering systems, companies can recuperate vital sources from utilized transformer oil while mitigating ecological threats.

Understanding Transformer Oil

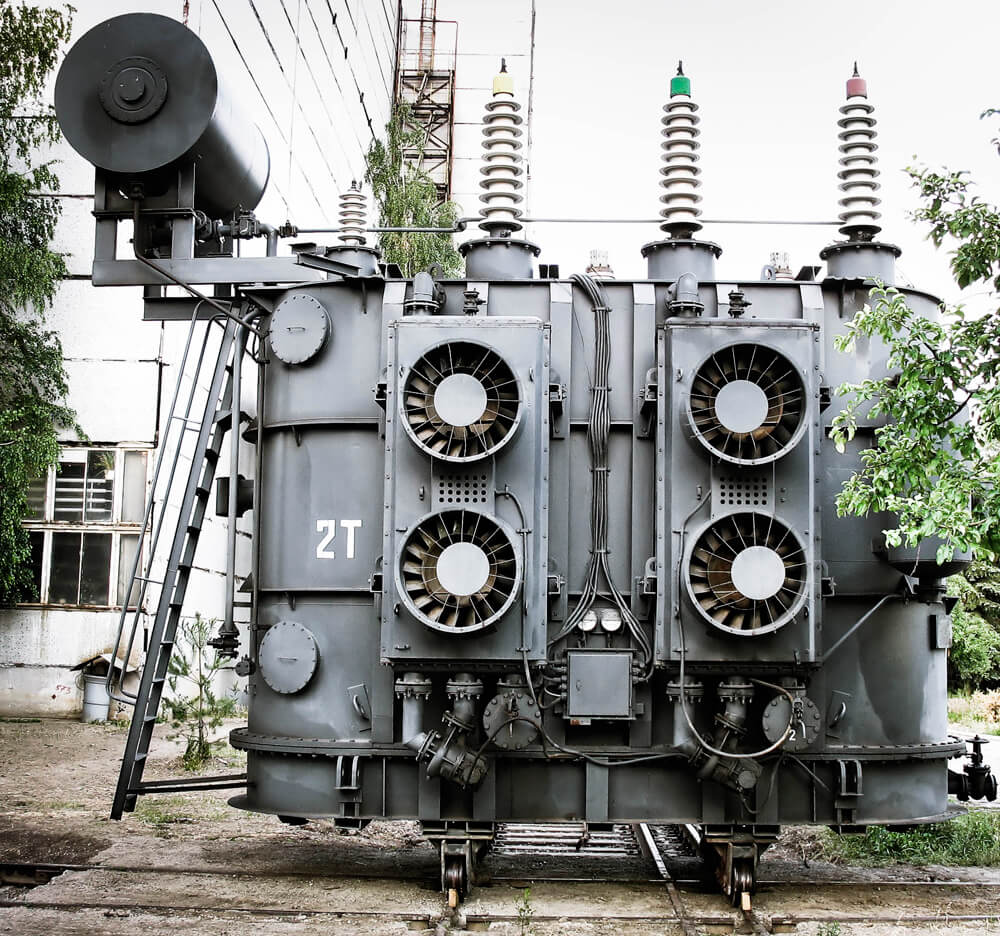

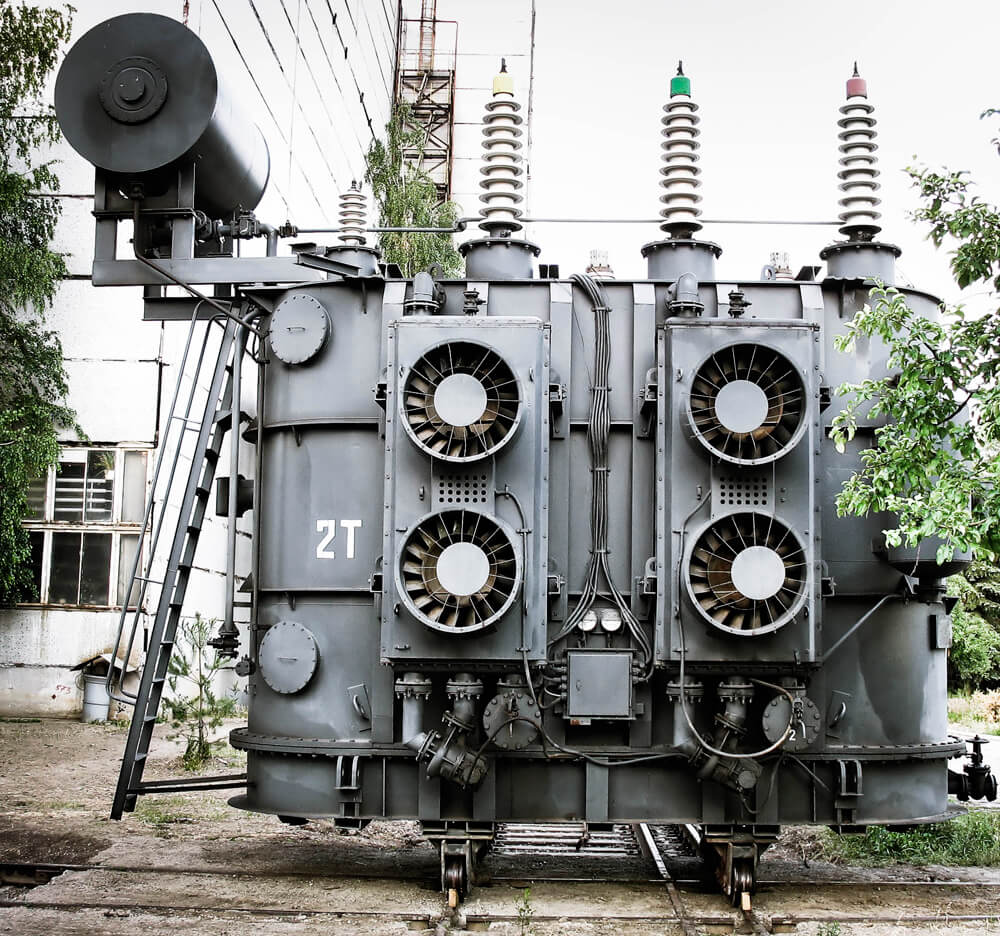

Transformer oil is a specific shielding and cooling down fluid used in electrical transformers to improve functional performance and reliability. This oil plays a critical function in protecting against electrical discharges and preserving the needed thermal balance within the transformer - Recycling Transformer Oil. It offers to protect the conductive parts, guaranteeing that power is efficiently moved while minimizing the risk of brief circuits

Typically stemmed from refined oil, transformer oil is defined by its high dielectric stamina, low viscosity, and a durable chemical stability that enables it to withstand raised temperature levels. The oil's ability to dissipate warm produced during procedure is essential; as transformers convert electric energy, they produce warm that should be successfully handled to avoid tools failing.

Furthermore, transformer oil is developed to stand up to oxidation and degradation, which can cause the formation of sludge and various other dangerous byproducts. Normal monitoring of oil high quality is vital, as pollutants can endanger its insulating residential or commercial properties and overall efficiency. Recognizing the structure and functionality of transformer oil is crucial for maintenance methods, guaranteeing the long life and functional stability of transformers in numerous applications across the power sector.

Value of Recycling

Why is reusing transformer oil essential for both ecological sustainability and economic effectiveness? The inappropriate disposal of transformer oil can result in serious environmental hazards, including soil and water contamination. By recycling this beneficial resource, we not just reduce these threats yet also add to a cleaner ecosystem. Used transformer oil consists of unsafe products that, if launched into the atmosphere, can damage wild animals and interrupt regional ecological communities. Recycling assists to avoid these damaging effects, reinforcing the dedication to ecological stewardship.

From an economic viewpoint, reusing transformer oil provides considerable price financial savings for services. The procedure permits business to recover a high-grade item that can be reused in numerous applications, decreasing the need for acquiring brand-new oil. This not only decreases functional costs however additionally decreases garbage disposal costs connected with hazardous products. Moreover, reusing sustains the round economic situation by transforming waste into valuable sources, thereby cultivating lasting methods within the market.

Advanced Recycling Technologies

As the need for sustainable techniques in the power industry expands, advanced recycling technologies have actually arised as a critical option for handling used transformer oil. These innovations incorporate a variety of cutting-edge approaches made to efficiently reclaim useful sources while minimizing environmental impact.

One popular method is vacuum cleaner distillation, which divides oil parts at reduced temperatures, preserving the top quality of the base oil while eliminating contaminants. This technique enhances the recuperation rate and makes certain that the recycled oil meets market criteria. One more considerable advancement is using adsorption and purification systems, which utilize specialized Re-refining Transformer Oil materials to record impurities and recover the oil's buildings efficiently.

Furthermore, the assimilation of chemical treatments, such as neutralization and decolorization, plays a crucial function in refining transformer oil. These procedures get rid of acids, sludge, and discoloration, leading to high-quality recycled oil that can be reused in various applications.

Economic and Environmental Conveniences

The economic and environmental benefits of transformer oil recycling are significant, providing a dual benefit for both market stakeholders and environmental conservation. By recycling made use of transformer oil, firms can considerably minimize operational prices related to acquiring brand-new oil, thus improving their profits. This process not just lessens garbage disposal fees but likewise enables the healing of beneficial materials, creating added income streams.

From an ecological viewpoint, recycling transformer oil adds to a decrease in contamination and source exhaustion (Transformer Oil Recycling). Appropriate recycling processes reduce the danger of harmful spills and dirt contamination, promoting and shielding neighborhood environments biodiversity. Moreover, repurposing transformer oil reduces the demand for virgin oil extraction, which commonly entails eco harmful methods such as boring and refining.

Furthermore, taking on sophisticated reusing innovations boosts compliance with strict ecological laws, thereby shielding business from prospective liabilities and fines. The positive impact on business social obligation initiatives can enhance a company's credibility, fostering higher trust fund and loyalty amongst stakeholders and customers. Basically, the environmental and economic benefits of transformer oil recycling emphasize its value as a sustainable practice in the energy industry.

Future of Transformer Oil Recycling

Building on the considerable financial and ecological advantages highlighted, the future of transformer oil recycling shows up encouraging, driven by technical innovations and increasing governing stress. Innovations in recycling technologies, such as improved filtering systems and chemical processing techniques, are anticipated to improve the performance and performance of oil recuperation procedures. These improvements not just reduce waste yet also maximize the quality of recycled oil, making it better for reuse in different applications.

Furthermore, as federal governments and regulatory bodies worldwide implement more stringent ecological guidelines, the need for lasting techniques will rise. This shift will certainly force sectors to embrace transformer oil recycling as a vital part of their functional strategies. Firms that focus on environmentally friendly techniques are likely to get a competitive side, attracting ecologically conscious consumers and stakeholders.

Verdict

The recycling of transformer oil through sophisticated technologies not just conserves beneficial sources yet additionally dramatically reduces environmental threats related to garbage disposal. By embracing cutting-edge techniques such as vacuum cleaner purification and filtration, the electric sector can boost sustainability while concurrently generating and lowering operational expenses earnings. As the concentrate on environmentally friendly techniques magnifies, the future of transformer oil recycling shows up encouraging, positioning firms to flourish in an increasingly open market that prioritizes sustainability and environmental duty.

Transformer oil is a specialized cooling down and insulating fluid utilized in electric transformers to enhance operational performance and reliability. Understanding the composition and capability of transformer oil is vital for upkeep methods, guaranteeing the longevity and functional honesty of transformers in various applications throughout the power market.

One popular technique is vacuum purification, which separates oil components at reduced temperatures, maintaining the quality of the base oil while eliminating contaminants. By recycling made use of transformer oil, business can considerably reduce operational prices linked with purchasing new oil, thus boosting their lower line. Repurposing transformer oil lowers the demand for virgin oil removal, which typically includes ecologically devastating methods such as exploration and refining.

Comments on “Enhancing Transformer Life Expectancy With Transformer Oil Purification Techniques”